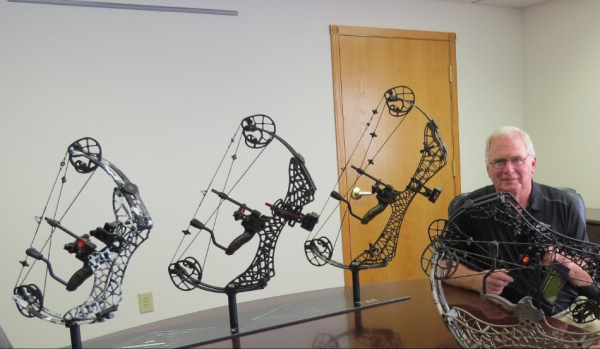

Eric Rapp, President/CEO of Gearhead Archery. Photo by Gearhead Archery

|

While I haven’t met Eric, I’ve known about Gearhead Archery since their inception and have followed their success since the humble beginnings of their T-18 bow. Eric has been more ‘behind the scenes’ at Gearhead and I’m curious to hear what his take on the company is going to be now that he’s in the spotlight. Therefore, it’s time for another edition of “5 Minutes…”

Q1: Eric, share with the Archery Wire readers what your role has been at Gearhead in the past, and then how that’s shifting now that you are the President/CEO. What new roles are you taking on in the company?

I supplied the resources to help incubate Gearhead Archery from the beginning. As owner of robotic equipment company, I had the facility, equipment and manpower to help Gearhead get off the ground quickly. I come from a manufacturing back ground where the culture is to make the best performing products at the lowest prices. We have the right products. The design of our riser makes the bow inherently accurate. I am taking a more active role to reduce our manufacturing cost so we can compete at a price point with the other bow manufactures.

Q2: What is on the horizon for Gearhead in 2019/2020? What goals or aspirations do you have for the company?

In 2019 we brought a new level of adjustability to our bow line not seen before. The development of the slider grip is a real game changer. Because our grip is not an integral part of the riser load, we can interchange grips very easily. We have three different slider grips at the current time: a Standard, 1911 and the Flat Back. We will continue to make advancements with our "Pick a Grip" system along with some additional cam development and a couple surprises. The goal has always been to be the leader through better engineering creating better performing products. It's okay to be different, people remember different. Give them different that gets results and that builds brand momentum. We are building a brand of quality performing product. Our bows are very accurate, that will be our message. We need to increase our sales efforts and we are always searching for talented people to help us.

Q3: What is personally your favorite bow in the lineup? Why is the company producing so many different bows and options? Is customizing the way of the future?

The T24 is my personal favorite. The compact size and maneuverability makes this the perfect hunting bow. We do have many different bow options! The design of our bow allows us to create different sized axle to axle bows by elongating the riser. Each bow also converts from right to left hand. People like what they like. Some want a 20" bow for hunting in tight spots and some want a 40" bow because of the string angle. Some desire speed while other want forgiveness. In the end, the customer is always right and we try to give the customer what they want. I don't think customizing is going away anytime soon. People like to put their individual flare on things, could be a car, boat, house or in our case a bow. At Gearhead Archery we give you options.

Q4: Thinking back to the ATA Show in January, Gearhead has had a shooting lane for some time now – what did you hear differently this year that you haven’t heard before?

Adjustability, adjustability, adjustability! This was the fourth trip to the ATA show for us. Our first year all we had was the T18 in one draw length, but in 3 different materials: Aluminum, Carbon Fiber and Titanium. We followed the T18 with T20, T24, T30, T33, T36 and M30. All of the these bows shoot amazing, but, were fixed to a specific draw weight and draw length. We could build them to whatever the customer wanted, but they have minimal capacity for adjustment. The new B Series introduced this year is fully adjustable. Brace height is adjustable in one bow, offering speed or forgiveness. The cam has a rotational module to change the draw length on the fly. A zero tolerance limb pocket adjusts 10 pounds. The slider grip moves left and right to take the grip torque out of the bow. The cam also has three different string posts, so it can be set up with different draw cycles to fit any archer's shooting styles. We built this bow with maximum adjustment.

This is why I love the archery industry so much – innovation, entrepreneurship, and frankly, not being afraid to try new things. Gearhead embraces all of that and it is showing in their rise amongst bowhunters and in tournaments. Thanks for reading. -Michelle Scheuermann, editor.